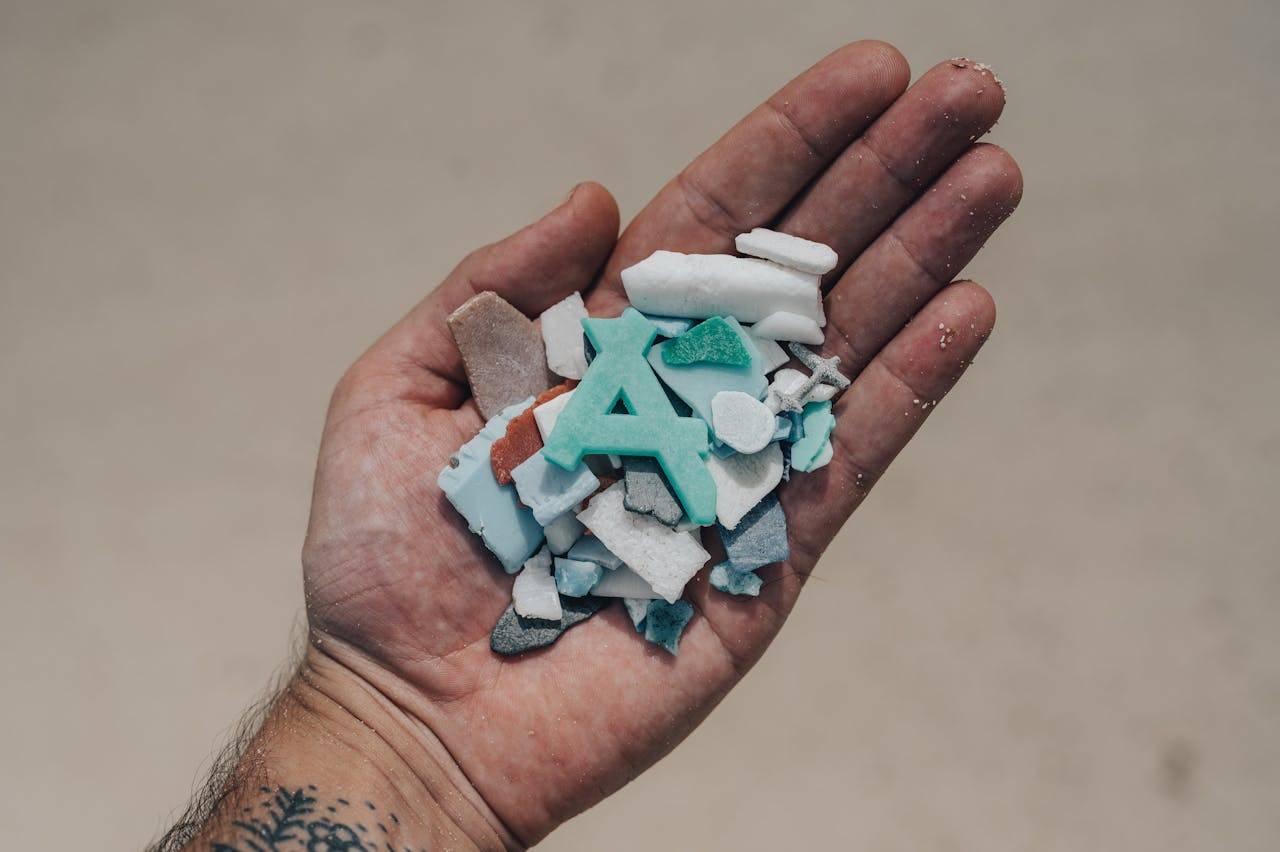

Make no mistake about it: Microplastics are a worldwide issue. It’s estimated that up to 28% may be caused by particulates from tire wear-and-tear, which gets into our water systems threatening, well, pretty much everything.

By Carter Hammett

As a first- time driver in Canada, it’s a good bet that Tyrone Fernandes hasn’t spent a lot of time thinking about the negative impact his tires may be having on the environment.

“I don’t have a lot of knowledge about cars,” he says, so I usually go by a referral.” Which is how the 51-year-old customer service representative purchased his first car, a 2019 Subaru Impreza, three years ago.

Arriving from his native Pakistan five years before, one of his main objectives was getting a driver’s license–a right of passage for many new Canadians– swiftly followed by purchasing his first car. Being a responsible driver, Fernandes was quick to purchase winter tires secondhand for about $350 after purchasing his car in November, just in time for winter.

“My safety and the safety of others is the most important consideration I have in mind when driving,” he says.

Fernandes says he spends an average of 50 minutes daily driving 30 km to-and-from work. That works out to about 600km per month. That in itself works out to about 66 grams of microplastics released into the environment from simple wear-and-tear on his tires.

It doesn’t sound like much does it? But every year, with billions of cars on the road world-wide, an estimated 6 million tonnes of tire fragments are released into the environment. These tiny plastic particles eventually accumulate in the soil in rivers and other bodies of water, even winding up in our food.

Nonetheless tire fragments have barely registered as a blip on pollution registers by themselves, because they’re often lumped in with other microplastics. It may be hard to believe but it’s been estimated that between 10-and- 28% of all microplastics entering the environment globally come from tire particles. Researchers are gradually realizing the unique characteristics and with that the problems, these pollutants can cause. Every year more and more evidence against microplastics accumulates, where it now appears that science is ready to classify microplastics from tires as their own separate category.

The problem has become so prevalent that a South China study conducted late last year found tire-derived chemicals in most human urine samples. As if that wasn’t enough to convince you, another study conducted between 2016 and 2024 and published this year in Nature Medicine, discovered that plastic levels in human brains jumped by over 50% (!)

It’s time we stepped back and took some time to reflect on this issue, the problems it causes and some of the solutions being developed in response.

So just what exactly are microplastics?

Microplastics can be defined as minute plastic particles less than five mm in length (about the size of a pencil eraser). These particles can be identified in a multitude of varying forms including fragments, beads, fibers, foam and other types of plastic that contain a myriad of chemical additives.

Even further off the radar are nanoplastics which are plastics that are one micrometer, or smaller. These particles are usually byproducts from the degradation of a larger plastic item. The smallest of these have been identified in water vapour and have been found everywhere from the Antarctic to the Andes (in rain).

“Tire and road wear particles (TRWP) are particles unintentionally generated at the frictional interface between the tire and roadway during use,” says Michal Majernik, Manager of Communications with the Tire and Rubber Association of Canada (TRAC).

“TRWP differ from most microplastics in their chemical and physical properties, as they contain both mineral and elastomer-based materials. This results in TRWP having distinct size, density and persistence characteristics as compared to most microplastics, necessitating different methods for their proper characterization.”

Canada produces about 26 million tires annually, part of the 3.1billion tires produced globally each year.

According to watershedsentinal.ca, as tires wear, it’s been calculated that 10-30% of the TWRP ends up in the environment. When looked at globally, that works out to an estimated 6.1 million tons of tire particles every year.

The smallest particulates, PM2.5, are considered to be extremely dangerous. The pollution these bits generate have been linked to a range of negative health conditions including respiratory, cardiovascular and developmental health.

In 2020 the Organization for Economic Cooperation and Development estimated that non-exhaust sources will dominate particulate emissions from road traffic as early as 2035 as tailpipe emissions dwindle.

Tires are composed of about a 60/40 blend of natural and synthetic materials. Elements like carbon black, aromatic oils, sulphur, silica and zinc are added to the mix to improve rolling performance and increase wear resistance. Once in the environment, tire particles can pose a serious risk to human and wildlife health through numerous pathways.

Understanding tire chemicals

One chemical byproduct considered essential for making tires is 6PPD which contributes stabilization to the rubber properties helping to preserve tire life. It’s designed to protect tires from ground-level ozone but when it interacts with ozone, it produces the water-soluable compound 6PPD-quinone which can be absorbed by any organism within proximity. The Sierra Club reports that it is this chemical, even at low levels, that is believed to have had a devastating impact on Coho Salmon in B.C. according to research published by a group of Washington scientists in 2021.

“Since learning of the effects of of 6PPD-quinone, the global tire industry has been working closely with regulators , material suppliers, academic and government research teams, industry associations and other partners to identify a potential alternative to 6PPD that is protective of motorist safety and the environment,” says Majernik.

“Tire industry in the U.S. is taking the lead on this issue and has mobilized a consortium of more than 30 tire manufacturers to conduct an alternative analysis for 6PPD in tires. The industry filed its Preliminary (Stage 1) Alternatives Analysis (AA) Report to California’s Department of Toxic Substance Control (DTSC) in March 2024. The industry’s stage 2 Alternatives Analysis report is due to DTSC in August 2026.”

Other tire components environmentalists have pointed to include zinc oxide, which accounts for about 0.7% of a tire’s weight. While zinc oxide is considered essential for adding to a tire’s durability, it is also highly toxic for aquatic life and even has the potential to disorder ecosystems even in small amounts.

“Tire manufacturers utilize zinc oxide because it is a critical ingredient that allows a tire to perform safely. Without zinc oxide, rubber tires cannot be manufactured,” says Majernik. “Tires are highly engineered, highly regulated products to ensure safety, quality and durability and our industry remains committed to collaborating with regulators and researchers to find potential meaningful and effective solutions that balance safety requirements with environmental concerns.”

Impact on human health

While much evidence has accumulated about the negative impact microplastics have on the environment, last year’s South China study that found microplastics in human brains raises significant alarm bells about the impact that microplastics potentially have on human health. And here we must mention a cautionary: while there can be no denying the challenges brought forward by the microplastics issue, it should be stated plainly that research in the field is still evolving and as such findings tend to vary depending on models and methodology used.

In 2005, the industry created the Tire Industry Project ( tireindustryproject.org) under the umbrella of the World Business Council for Sustainable Development (WBCSD). This is a voluntary CEO-driven initiative with a mission to anticipate, understand, and address global environmental, social, and governance (ESG) issues relevant to the tire industry and its value chain. The organization currently brings together 10 leading tire companies that represent more than 60% of the world’s tire manufacturing capacity.

“To improve understanding of potential human exposure to TRWP, The Tire Industry Project’s (TIP) ongoing and planned research includes topics around sampling of TRWP in the environment and studying its degradation. To accelerate such knowledge gathering, TIP also creates public platforms such as research conferences to cross-fertilize ideas and open calls for projects to fund research initiatives.”

Majernik acknowledges that the impacts of TRWP are complex and states that the tire industry supports this evolving area of research and supports ongoing studies that advance understanding. He points to recent studies for example, that suggest that TRWP is not considered a major risk to people through airborne exposure.

Auto recycling

According to autorecylers.ca, Canada has a 2030 target for zero plastic waste. About 1.6 million vehicles are retired in Canada annually. Every end-of-life (EOL) vehicle contains approximately 175kg of varying plastic resins. But there are currently no markets available for many of the plastics found in vehicles, in part because these plastics tend to be contaminated with with other plastics and metal components and currently no technologies exist to recycle the different components.

“We know for a fact that the plastics from lead-acid batteries – the product with the highest recovery rates, even higher than vehicles – virtually all of the plastics are recovered and recycled. Same thing with headlamps and bumpers – thousands re-used and even recycled every day. But lots of work still to do,”

says Steve Fletcher, co-Executive Director of the Ontario Automotive Recyclers Association (OARA).

A partial response to this was a multi-phase study launched by the Automotive Recyclers of Canada (ARC) in 2022. “The objective of the ARC Auto Plastics Roadmap was to identify the research steps, projects and activities needed to increase the recycling of pre-shredder auto plastics in Canada.”

A key outcome of the project was the recommendation of several steps needed to move Canada towards a circular economy for auto plastic, including:

- “Action #1: Clarify the federal government and CCME’s plans and actions to achieve zero plastic waste by 2030.

- Action #2: Engage the Canadian automotive industry to become leaders in policies, plans and actions to increase automotive plastics reuse (e.g., dismantling) recycling and recovery (i.e., from auto shredding processes) and to reduce overall automotive plastic waste generation.

- Action #3: Measure and track reliable data on current auto plastic waste generation, reuse, recycling and auto plastics waste diversion

- Action #4: Establish a multi-stakeholder body to focus on automotive plastics and other after-market critical issues

- Action 5: Investments in auto plastics reuse/recycling innovations, collection and processing infrastructure and skills training are critically needed.

- Action #6: The Canadian and global automotive sector is undergoing profound and positive changes. The ”re-make” of the industry towards electric vehicles presents a unique opportunity to begin to design new EV products with “Design for Environment”, allowing for easier removal of plastics for repair, reuse and recycling in mind.”

“The Roadmap also looked at the economics of pre-dismantling vehicles to recover plastics – that showed that it is prohibitively expensive and unless consumers want to pay a huge eco-tax when they buy a new car – that will probably never work,” says Fletcher.

“We are following closely regulations in the EU where they require 25% of plastics in new cars to be recycled and 25% of that to be from ELVs. That is providing incentive to the OEMs to help create markets. We have had discussions with two OEMs on this as they try to understand what is happening now, and presumably pushing that information back to their suppliers.

“Federally, they have introduced a plastics registry where manufacturers need to document what plastics they are putting on the marketplace and eventually what is happening to those plastics – again beyond recycling and in to the more sustainable activities of reuse, reman, repurposing, etc. That initiative is driving OEMs to reach out to auto recyclers to find out what is happening – and the Roadmap has been the perfect tool to get them involved,” says Fletcher.

More information about the study can be found at: https://autorecyclers.ca/plastics-from-elvs-study/

Other solutions being studied

But auto recycling isn’t the only solution that’s being looked at. Microplastics is an undeniable global concern and there are signs of hope as scientists worldwide attempt to tackle the issue.

One area making significant inroads is the development of green tires. Green tires incorporate components such as recycled rubber and plant-based silica which reduces waste and enhances sustainability. This relatively new innovation helps to lessen a dependence on non-renewable resources while promoting sustainability in the manufacturing process. Green tires offer cost savings to drivers by using less energy to propel a vehicle forward, contributing to fuel conservation in the process.

Tire manufacturers are investing heavily in green tire solutions. In 2024, Toyo Tires unveiled a concept tire composed of 90% sustainable material, implying a giant leap forward towards sustainability. Components include bio-derived polyester fiber, rice husk, ash silica and recycled bead wire among many others. Industry is taking note and responding to consumer demand for durability and environmental impact.

Another solution that appears to hold much promise is a plastic that dissolves in seawater within a few hours.

Researchers in Wako Japan claim the material is comparable to petroleum-based plastics in terms of strength but breaks down to its original components when exposed to salt. These materials can also be processed by adding naturally occurring bacteria, which in turn sidesteps the generation of microplastics, avoiding harm to aquatic life in the process.

The material can be used just like regular plastic when coated, and researchers are now focusing research on the best coating methods. Researchers claim the plastic to be non-toxic, non-flammable, and does not emit carbon dioxide.

Other global approaches include a process where UK researchers are studying fungi and bacteria that feed on plastic, breaking it down in the process. Over in Australia, a species of beetle larvae that feeds on polystyrene has also offered another potential solution.

In 2024 the federal government of Canada, announced $2.1 million in funding over four years to McGill University, Memorial University and the University of Toronto to undertake research related to exposure to microplastics from various sources including food, food packaging, drinking water, indoor and outdoor air as well as dust. Among the projects currently active is one at The University of Toronto where researchers are looking at using water filtration techniques or chemical treatments that can remove microplastics.

Personal responsibilities

While science does the heavy lifting, efforts to find and implement a potential alternative to 6PPD (while still complying with safety standards) will take time, there are things that can be done now to reduce 6PPD and 6PPDQ in the environment. These measures include street sweeping in urban areas, choosing pavement surfaces (such as rubber modified asphalt and permeable pavement) that reduce tire abrasion and mitigate stormwater impacts, installing bioretention technologies to treat stormwater, and maintaining proper tire inflation to reduce tire abrasion

Majernik suggests that consumers have a role to play as well. When it comes to tires, proper tire maintenance and efficient driving habits will keep tires on the road longer and lower the overall environmental impact of driving.

TRAC recently conducted a consumer survey that highlights the disconnect between drivers’ awareness of the importance of tire maintenance and their actions. The majority (89 per cent) of Canadian drivers agree that proper tire inflation and maintenance are more beneficial than ever, as it improves fuel economy and increases tire longevity. However, this essential practice often goes overlooked and many drivers lack the knowhow about proper tire maintenance, including determining the correct tire pressure for their vehicle, and the right time and the right interval for checking tire pressure.

Drivers wanting the highest fuel savings should consider using fuel-efficient tires in combination with monthly tire inflation checks and fuel-friendly driving habits such as maintaining a steady speed, accelerating gently and coasting to decelerate. Other fuel-efficient driving techniques include limiting air conditioning; not revving or idling your engine and removing roof or ski racks. According to Natural Resources Canada, these fuel-saving driving practices alone can cut fuel consumption by up to 25%.

These behavioural changes can contribute much to the evolving realm of green sustainability and form a link in the interdependency between consumer demand, driver responsibility and industry solutions.

Says Majernik: “The tire industry is one of the oldest industries in the modern era, and it is integral to mobility but also a key player in the shift toward sustainability. From recycling to eco-innovation, the industry is working continuously to balance performance, safety, and environmental responsibility.”